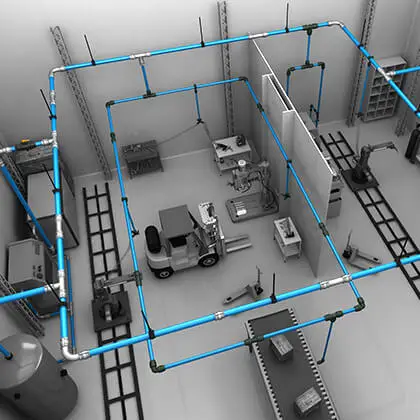

Install a Reliable Copper Compressed Air System for Your Shop

A Copper Compressed Air System is the top choice for commercial spaces and shops looking for reliability and efficiency. Copper’s natural resistance to corrosion ensures a clean, uninterrupted airflow, maintaining optimal performance over time. This material withstands high pressure and temperature fluctuations, making it perfect for the rigorous demands of industrial environments. With its smooth interior, copper minimizes friction, promoting consistent airflow and reducing energy loss. Choosing a Copper Compressed Air System means investing in a durable, low-maintenance solution that supports productivity and enhances your overall operations.

What is Compressed Dry Airline (CDA) copper piping Installation?

A compressed dry air copper piping (CDA) is used to deliver compressed dry air to areas where needed (labs, warehouse, equipment etc.). Compressed dry air is considered essential to production and is used in many commercial / industrial facilities. A poorly designed CDA system can increase energy costs, cause equipment failure, reduce production efficiencies, and increase maintenance requirements.

At WCI, we are committed to help you select and design the most effective compressed air system via copper piping for your needs – that includes considering demand, compressed air quality, supply, storage, distribution, installation, maintenance, copper piping, and condensate management. We understand how critical it is to keep all of your tools and machines that require compressed air to continuously work efficiently.

Let us know about your project of copper piping so we can answer your questions and provide an estimate. You can also use our contact us page to send your query and recommendations to us.

Our Copper Compressed Air System Installation

Compressed air line installations

CDA design and installs

CO2 piping

Nitrogen piping

Chilled water loop piping

Emergency shower installation

EXPLORE MORE

As we’ve considered, copper stands out as a top choice for compressed air systems in industrial spaces due to its durability, resistance to high pressure, and temperature stability. Copper’s smooth interior ensures efficient airflow with minimal energy loss, making it a reliable and cost-effective solution for many commercial applications.

However, in cleanroom environments where strict air purity and contamination control are vital, stainless steel or specialized plastic pipes often take precedence. These materials prevent particle shedding and maintain high levels of cleanliness, ensuring compliance with stringent cleanroom standards.